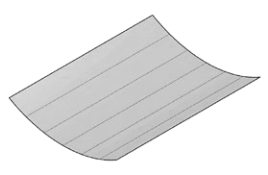

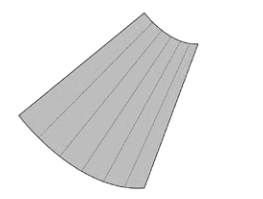

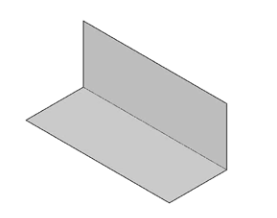

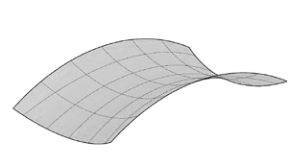

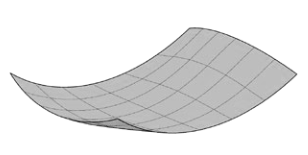

Developable panels

Developable panels are folded and bended panels as per fig. 1, 2 and 3. These panels do not need stretch/elongation, on any line and can be ‘flattened’ again with minor efforts.

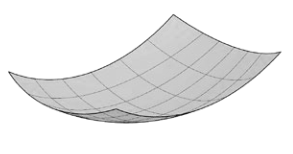

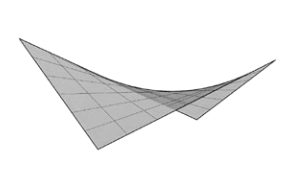

Non developable panels

Non-developable panels however, as per fig. 4, 5, 6 & 7 below are quite different.

In combination with a rolling unit

It requires spatial awareness from the observer to see that certain lines in these panels need elongation in order to get the actual shape. These non-developable panels will be produced by bending, in combination with a rolling unit for stretching.

In general shipbuilding, vessels comprise an average 17 % of non-developable panels. More specifically, large containerships might have only 15 % double curved panels, but offshore supply vessels even up to 20 %.

Weakened panels?

The stretching technology can lead to minor thinning of the panels on the stretched lines. This sometimes raises questions from the design engineers, as to if this will this weaken the panel?

Not at all.

Practical and calculated quality checks revealed a -0,065 mm thinning on a 25 mm panel when a common and average elongation of 2,6 mm / frame section is applied.

Note: the applicable IACS-UR W13 standard clearly allows a thickness tolerance of -0,8 mm for a 25 mm panel. Hence, thinning by cold forming is not an issue.

Average production time: 8x faster

The average production time for panels is 3-4 hours which can be achieved after a successful 12-week training period and practical experience over one to two years. We also recommend clients to opt for a short repeat training of 4 weeks, 12 months after the initial training.

This makes the production time of panels approximately eight times faster than line heating while getting new operators up to speed in significantly faster.

COLD FORMING IS THE RIGHT ALTERNATIVE FOR LINE HEATING AND THE RIGHT SOLUTION FOR SHIPYARDS TO CREATE COMPLEX HULL PANELS.